nanoindentation hardness testing|oliver pharr method nanoindentation : trader The nanoindentation test is a depth-sensing indentation (DSI) technique that can probe a small volume of a sample to measure the mechanical properties of stiff and hard materials at the micrometer and nanometer scales [14]. . Nanoindentation test is similar as a microscale hardness test. The modulus and hardness at each indentation point can . Choose from an assortment of polypropylene pans, trays and baskets for autoclaving and sterilizing labware and instruments. Plastic construction is quieter than metal pans, and doesn't dent or corrode.

{plog:ftitle_list}

Lab autoclaves are essential equipment used in laboratories for sterilizing various materials and equipment. These highly efficient machines use steam under high pressure to eliminate bacteria, viruses, and other .

The results of the nanoindentation test provide the necessary data for the analysis of the elastic modulus, hardness, strain hardness, cracking, phase transformations, creep and fracture toughness of the material.Nanoindentation, also called instrumented indentation testing, is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials. The nanoindentation technique was developed in the mid-1970s to measure the hardness of small volumes of material.

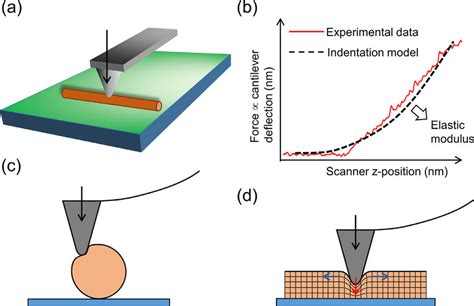

Nanoindentation tester NHT³ measures the mechanical properties of coatings and bulk materials such as hardness, elastic modulus, and viscoelastic properties from the nano- to the microscale. . The NHT³ Nanoindentation tester is designed for measuring hardness, elastic modulus, creep, and other surface properties from the nanometer to the .→ can measure mechanical properties (e.g. modulus, hardness) on areas nm-μm scale; e.g. thin films and small volume structures → called "nano" since the indentation depth is of nanometer scale,The nanoindentation test is a depth-sensing indentation (DSI) technique that can probe a small volume of a sample to measure the mechanical properties of stiff and hard materials at the micrometer and nanometer scales [14]. . Nanoindentation test is similar as a microscale hardness test. The modulus and hardness at each indentation point can .Nanoindentation Testing 2.1 Nanoindentation Test Data The goal of the majority of nanoindentation tests is to extract elastic modulus and hardness of the specimen material from load-displacement measurements. Conventional indentation hardness tests involve the measurement of the size of a

why are indenters small

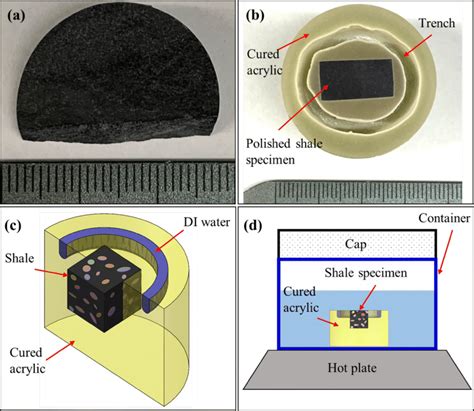

sample preparation nanoindentation

nanoindentation hardness testing in structural alloys. We selected. the FeCr alloy system due to the ability to explore a wide range of. hardness levels in single-phase (solution hardened) and dual-

This work presents fundamental understanding of the correlation between nanoindentation hardness and practical scratch resistance for mechanically tunable anti-reflective (AR) hardcoatings. These coatings exhibit a unique design freedom, allowing quasi-continuous variation in the thickness of a central hardcoat layer in the multilayer design, with minimal . The nanoindentation test is utilized to measure the hardness and elastic modulus of various components within Ceramic Matrix Composites (CMCs), including continuous stiffness measurement (CSM) and quasi-static testing. . The elastic modulus and hardness of the simulation are determined based on the elastic modulus and hardness of the previous .

oliver pharr method nanoindentation

Nanoindentation is a method for testing the hardness and related mechanical properties of materials, facilitated by high-precision instrumentation in the nanometer scale, as well as analytical and computational algorithms for result evaluation.Nanoindentation (NI) is a nano-mechanical test that provides the mechanical properties from precise compliance measurements. In addition, nanoindentation analysis is especially useful in measuring properties such as the modulus and hardness of various shaped and sized materials.Nanoindentation has advantages over traditional mechanical testing, providing both elastic modulus and hardness data from a single test. Integrated indentation testing (IIT) automates the indentation process so hundreds of tests with micron spatial resolution can be performed on a small sample size.In a traditional hardness test the size of the residual indent impression needs to be physically measured to obtain a hardness value (function of applied force divided by the size of the indent impression). . The Hysitron Performech Advanced Control Module sets the standard in nanoindentation control technologies and delivers industry-leading .

nanoindentation tips

Hardness testing is widely used to evaluate the plastic deformability of materials. In the last few decades, nanoindentation testing methods [8,9,10,11,12,13,14,15,16,17,18] have been developed and are rapidly becoming widespread for the evaluation of various materials, including steels , tungsten , copper , and NiTi alloys . This has produced . To measure nanomechanical properties of surface layers of bulk materials and thin films, depth-sensing nanoindentation measurement techniques are used commonly. The nanoindentation apparatus continuously monitors the load and the position of the indenter relative to the surface of the specimen (depth of an indent or displacement) during the indentation . We note that by simply restricting nanoindentation testing to the most common test techniques–using Berkovich probes and Oliver–Pharr data analysis, . Nanoindentation hardness measurements of mineralized tissues. J. Biomech., 39 (2006), pp. 2699-2702. View PDF View article View in Scopus Google Scholar. Oyen, 2006b.In this article, the methods and testing theories of indentation at ambient and low temperature, including micro-hardness testing and nanoindentation testing, are introduced. Several stages of nanoindentation systems capable of testing at low temperatures are discussed in detail. The major design elements featured in the systems are described .

Hysitron nanoindentation systems include a quasi-static data analysis package that uses a standard model to fit the initial unloading portion of the force vs. displacement curve to extract the Reduced Modulus (E r) and Hardness (H) values.Quasi-static testing enables the nanoindentation probe area function to be calculated using an advanced analysis software package to ensure .Nanoindentation - Indentation forces ranging from 1µN to 100 mN can be made to measure material hardness. Indentation depth or area is inversely proportional to hardness. Indentation depth or area is inversely proportional to hardness.In-situ and Small-Volume Fracture Toughness Measurement via Nanoindentation. For hardness testing via nano/micro indentation, any cracking caused by sharp indenter tip and excessive load is undesirable and will lead to questionable data. However, such phenomenon and capability has been proven to be very useful in evaluating one of the critical .

Nanoindentation hardness testing was used to analyze ultra-thin gold films before and after vacuum annealing, deposited on two different substrates. NanoBlitz 3D and Express Test results showed a significant decrease in indentation hardness of the gold metal films. Download PDF. Nanoindentation testing is a fairly mature technique which uses the recorded depth of penetration of an indenter into the specimen along with the measured applied load to determine the area of contact and hence the hardness of the test specimen. Many other mechanical properties can also be obtained from the experimental load–displacement .

nanoindentation tests

Introduction. Hardness as a mechanical property is a convenient parameter to assess a material’s strength, since it is intuitive that a harder material will be able to penetrate a softer material, but not vice versa [Citation 1].Nowadays, it is possible to maximize the output of instrumented indentation experiments, since the contact stiffness and thereby also the .

difference between autoclave and tubular

Instrumented indentation testing, also called nanoindentation, is one of the hardness measurement methods. As an important component of material testing, it is used to determine plastic and elastic material properties such as Martens hardness HM, Indentation modulus EIT, Indentation hardness HIT and Indentation creep CIT.. In contrast to the classical hardness .Nanoindentation testing involves the use of a hard tip material (such as diamond), known as the indenter, to press into the surface of the sample of the material being examined. . In this article, the indentation load is selected as 5 mN using the NanoTest Vantage system to measure the micro-hardness. This nanoindentation instrument is an .

Nanoindentation hardness testing was used to analyze ultra-thin gold films before and after vacuum annealing, deposited on two different substrates. NanoBlitz 3D and Express Test results showed a significant decrease in indentation hardness of the gold metal films. Download PDF.

difference between autoclave and ultraclave

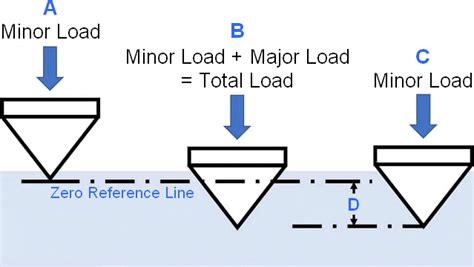

Hardness and Nanoindentation Disclaimer: These slides do not contain the original work of the instructor. . Hardness test is often used due to simplicity of both the test procedure and sample preparation. However, results are often comparative. The most common uses for hardness tests is to verify the heat treatment, Unlike the static hardness test, during a high strain rate indentation test, the load experienced by the sample can differ greatly from the force generated by the actuator due to the significant additional contribution to the load from inertia and damping occurring in the instrument. . In quasi-static nanoindentation testing, the load (P) is . The purpose of this study was to systematically evaluate, via nanoindentation testing, the hardness of the ferrite and martensite present in a series of commercially produced DP980 steels, and to correlate the measured hardness with macroscopic mechanical properties, including Vickers hardness, tensile properties, and hole expansion data.

difference between autoclave and ultrasonic cleaner

difference between autoclave and uv sterilizer

【Solved】Click here to get an answer to your question : All of the following are components of an autoclave EXCEPT: valves. temperature gauges. a pressure chamber. pressure gauges. .

nanoindentation hardness testing|oliver pharr method nanoindentation